About

Cavitator Systems

Cavitator Systems is the manufacturer of the patented, cavitative mixing technology for all pumpable media for the production of particularly homogeneous mixtures. So far, the focus has been on the demanding beverage industry. Applications in other industries are possible. Cavitator Systems offers process engineering solutions from individual systems to turnkey systems.

Cavitator Systems GmbH offers innovative process solutions for the treatment and manufacture of beverages. A team of experienced engineers and master brewers designs and builds equipment for the requirements of advanced beverage production. The highest standards of hygiene are met. Systems can be delivered in standard or aseptic execution.

We have been successfully operating on the worldwide market since 2005 with the groundbreaking application of cavitation to the intensive mixing of liquids as well as liquids and gases.

Our patented CAVSYS®Cavitator is excellently suited to the fine beaded binding of gases and ingredients and to the stabilising of products which tend to foam - even at high product temperatures. In practice results are achieved which far surpass conventional solutions.

Through the combination of high tech, standardised components of high quality and modular construction we offer tailored solutions - for example, from the "Anti-Foaming" or "Carboniser" systems, through mixers to complex process equipment - from "water treatment to the filling machine".

Other business sectors for Cavitator Systems GmbH are our process solutions in the fields of foodstuffs, chemicals, cosmetics, pharmaceuticals and treatment of substrate in production of biogas. Knowledge obtained in the fields of mixing, homogenisation, emulsification and dispersing is put to use in appropriate future applications.

Increased Performance

With our cavitator system carbonic acid is dissolved by approximately 100%. The gushing reaction is essentially suppressed, the filling performance is increased up to 40%. During the passage the product does not experience any frictional heat by cavitation. The quality is preserved or even ameliorated by the fine dissolving of the CO2.

Saving Energy

With a cavitator system cooling can be reduced or even renounced - with constant performance. Cavitation technology enables bottling of products with a higher temperature. Energy costs are reduced dramatically.

A further advantage is: bottles, wet by condensation are a matter of the past.

With PET-bottles it was possible to increase filling temperature from 12 up to 18 °C, (54 °F up to 64 °F) resulting in a reduction of 8/9 of the energy consumption comparative to a cooling solution.

Application range on the basis of cavitation technology:

- mixing / blending

- homogenisation

- carbonation

- oxygen enrichment

- antifoaming of gushing products

- water treatment

Further services in plant engineering and construction:

- premix

- flash pasteurizers

- syrup room

- CIP systems for production and tank farm

- pipeline route planning

- planning and engineering

- concepts for processing plants or sections

mixing, emulsifying & homogenizing

Innovative process engineering solutions in the area of beverages, food, chemicals, cosmetics and pharmacy.

Cavitation

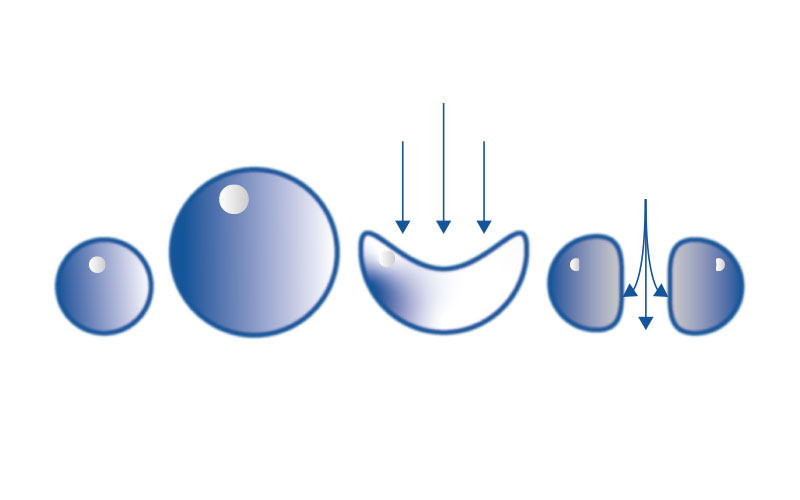

Cavitation is a physical phenomenon, that can be applied for interblending fluids or fluids with gases to intensify and amiliorate the results. Cavitation can be defined as the formation of cavities in liquid media which are caused by a localized under-pressure below the gas pressure of the respective fluid. After a short time these bubbles implode transfering energetic shock impulses to the liquid.

Learn More

Selected references

CAVSYS® Cavitator e. g. mineral water, flavoured water, CSD, juice, spritzer, energy drinks, wine, sparkling wine, fruit wine, cider, RTD, beer and other mixed beverages

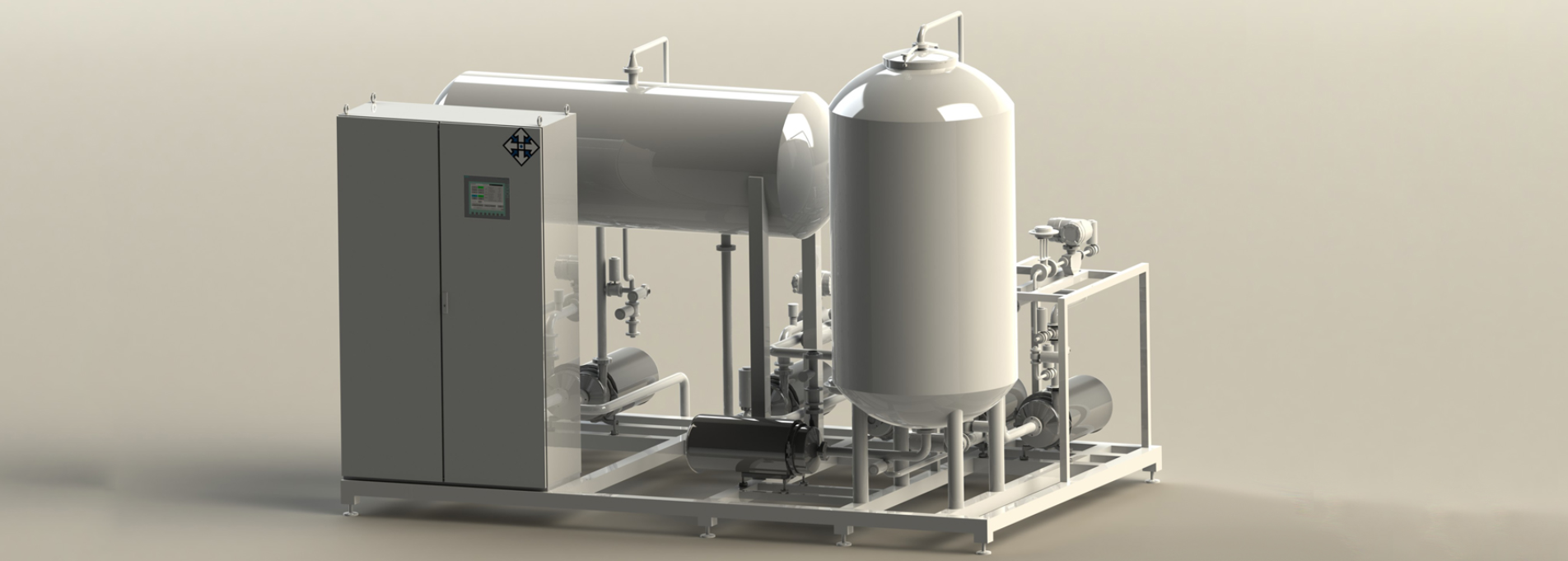

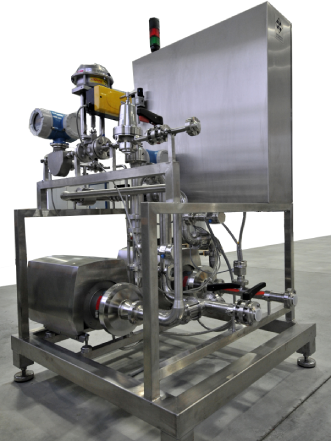

Inline carbonating unit

Inline carbonating unit combined with 1 tank CIP process

Inline carbonation plant with buffer tank