mixing, emulsifying & homogenizing

Innovative process engineering solutions in the area of beverages, food, chemicals, cosmetics and pharmacy.

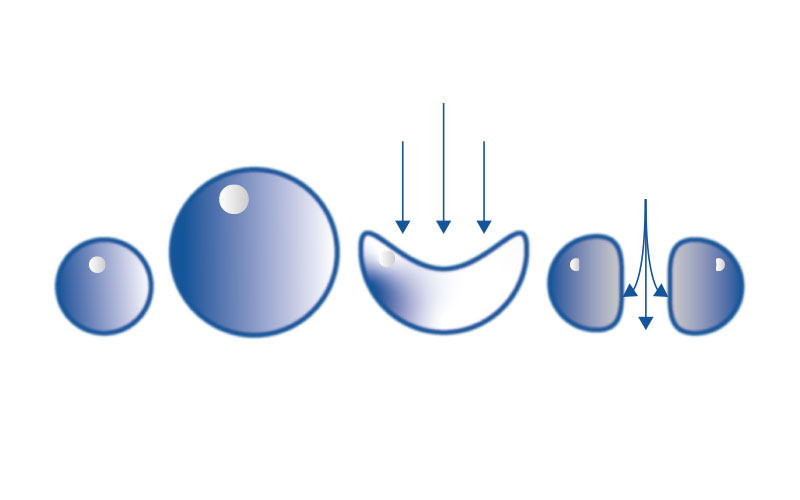

Cavitation

Cavitation is a physical phenomenon, that can be applied for interblending fluids or fluids with gases to intensify and amiliorate the results. Cavitation can be defined as the formation of cavities in liquid media which are caused by a localized under-pressure below the gas pressure of the respective fluid. After a short time these bubbles implode transfering energetic shock impulses to the liquid.

Technology

In Cavitator Systems' patented invention, gravitational forces and energy supply in the product flow are used to generate cavitation bubbles several times, the implosion of which is used to produce a high-energy and thus highly effective mixture and homogenization of gas / liquid and liquid mixtures. The shock pulses produced by the cavitation bubble implosion break up larger product components (for example gas bubbles), which are thus more finely distributed in the product. Thus, after passing through the CAVSYS® Cavitator, a homogeneous product with finely divided components results.

Research and Development

Mixtures of different consistencies such.

- Fruit juices

- Water / CO2 and water / O2 mixtures

- Oils and water / oil mixtures (diesel, machine, feed and crude oil)

- Water / silicone, graphite, and wax mixtures

- Colors and pastes

were effectively blended and and show stability and durability that are considerably higher than any other known products.The influence of the cavitation effect on the droplet distribution of emulsions, such as the homogenization of milk, was tested at the Biotechnical Center of the Weihenstephan University of Applied Sciences.